Thermal transfer ribbon

Among digital printing systems, the process of thermal transfer on labels stands out for its superior print quality.

Its colour covering and resolution guarantee barcode legibility, thus ensuring results that surpass the latest generation of ink/wax jet systems, even for small sized codes.

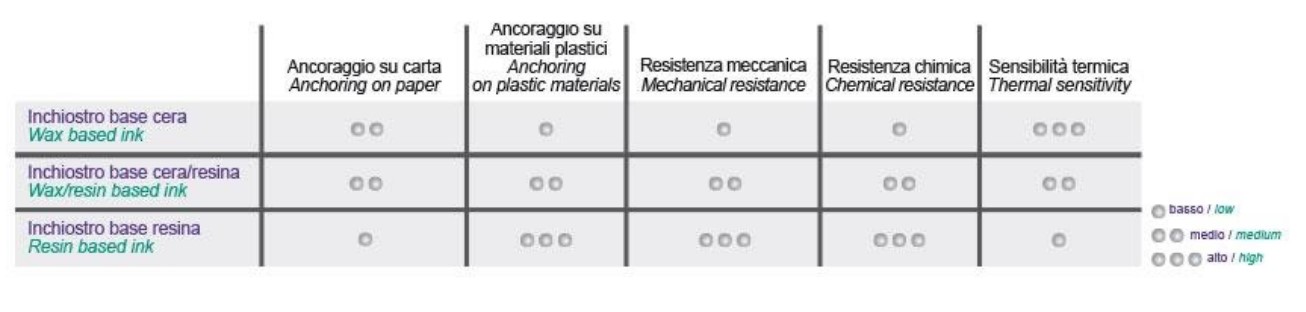

A broad range of available ribbons allows users to select the right pigment for their specific printing needs, ensuring compatibility with the label material selected; specific projects can be developed to totally satisfy all readability and indelibility requirements

The “Thermal Transfer Ribbon” comprises a polyester support (liner) with one side covered by a veil of dry ink (1-1.5 g/sq.m.), available in pigments of various colours and compositions.

On the opposite side, the liner is specially treated with a “back coating” to scroll along the printing head without damaging it, that is, at low friction and without generating electrostatic charges. The use of good quality ribbon is thus an important factor both for graphic yield and towards containing operating costs

Two types of thermal transfer ribbons exist, depending on the printing technology adopted: “flat” or “near-edge” (from the position of the thermal head).

“Flat” technology used by print apply print modules (e.g. Sato and Zebra) guarantees a greater life expectancy for the heads, and allows for the use of more economical ribbons.

“Near-edge” technology is indispensable only when using encoders with a horizontal head movement (e.g. Dataflex).

Related products

We work with the main industry sectors

Find the label that's right for you

We work with the main industry sectors